Yamaha, SMT Hybrid Packaging 2017’de En Son Gelişmiş Ürünlerin Tanıtımı Sonrasında Avrupa’nın Birçok Üreticisinin Geleceğe Yatırım Yaptığını Söyledi. Zİyaretçiler en üst düzeyde yetenekleri olan Yamaha’nın sunduğu Ultra kompakt YSM40R 200,000CPH dizgi makinesi, yüksek performanslı 3D AOI makinesi seçenekleri gibi makineleri arıyor.

Yamaha Motor Europe IM, bu ay sınırlı üretim alanını en üst düzeye çıkarmak isteyen küçük şirketlerden, çoklu hatları iyileştiren büyük üreticilere kadar, Mayıs ayında Nürnberg’de SMT Hybrid Expo 2017’de elektronik imalat sektörü yelpazesinde ziyaretçilerini ağırladı.

Yamaha Motor Europe IM İşletme Genel Müdürü Ichiro Arimoto, “Bu yılın SMT sergisi son derece başarılıydı, yüksek sayıda ziyaretçinin yeni nesil montaj yeteneklerine yatırım yapmak için yeşil ışık yaktı” dedi. “Büyük hesaplarımıza ve potansiyel yeni müşterilerimize başarılı bir şekilde bağlandık ve yeni YSM40R dizgi makinemiz ve gelişmiş yazılım araçlarımız gibi yeniliklerin, işletmelerini ilerletmelerine nasıl yardımcı olabileceğini gösterdik.”

Yamaha’nın 200.000 cph’lik YSM40R 4 Beam 4 kafalı mounter’in 1 metrelik geniş ayak izi hayal gücünü yakaladı. Devrim yaratıcı verimlilik için tasarlanan YSM40R, yüksek hızlı hareket kontrol algoritmaları, yeni RS yerleştirme kafası, durdurmayı en aza indirgemek için nozzle self diagnostic ve self restoration özelliği ve öncesi ve sonrası için yeni bir yüksek hızlı yan görüş kamerası sunar.

Çok ödüllü makine aynı zamanda dizgi hassasiyetini ve montaj güvenilirliğini arttıran yeni bir yüksek sertlikte taban çerçevesine sahiptir.

YSM40R’nin yanı sıra Yamaha’nın Yüksek Verimlilik dahil mounters serisi, çeşitli üreticilerden ilgi gördü. 90.000 cph sınıfının başında gelen YSM20, akıllı bileşen şekli tanıma, kayıklık telafisi, Yamaha’nın “1 kafalı çözümü (1 Head Solution)” ve hızlı değişimler için özel tasarım özellikleri ile yüksek hız, esneklik ve verimliliği birleştiriyor. Geniş gövde YSM20W, LED aydınlatma, medikal görüntüleme ve Cloud-sunucu montajları gibi normal PCB boyut sınırlarının ötesine geçerek yüksek değerli işleri gerçekleştirecek kadar büyük bir platformda aynı performansı ve güvenilirliği sunar.

YSM40R ve YSM20 / YSM20W dahil olmak üzere tüm YS dizgi makinaları, yüksek hacimli üretimdeki verimliliği artıran Yamaha’nın gelişmiş Otomatik Yükleme (AL) feederlarına ve bileşenlerin kısa bantta sunulduğu small batch işlere hazırdır. Yeni bant, feeder çıkmeden takılır ve kafanın kalibrasyonu doğruluğunu korur.

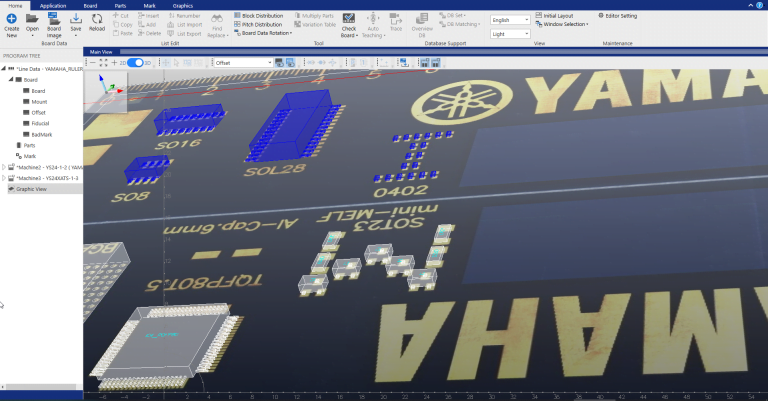

Pek çok ziyaretçi, Yamaha’nın varlıkları fabrika genelinde bağlanabilme, aktiviteleri koordine etmeye yardımcı olma, ekipman kullanımını ve çalışma süresini en üst düzeye çıkarma ve ürün kalitesini ve end of line verimini artırmaya yönelik çözümlerini görmeye geldi. Bunlara, software ekipmanlarını optimize etmek için inceleme verilerini gerçek zamanlı olarak analiz eden QA Opsiyon yazılımı ve dikkat edilmesi gereken durumlarda denetçilere otomatik olarak başvuran Mobil kıyaslama da dahildir. Buna ek olarak, Yamaha makineleri, otomatik zamanında yenilemeyi yönetmek için üreticilerin komponent depolama stoklarına sorunsuz bir şekilde bağlanır ve kurulum, izleme ve izlenebilirlik için güçlü isteğe bağlı araçları da bulunur. Buna ek olarak, iProDB, makine verilerini tarihsel olarak analiz etmek ve daha yüksek kalite ve üretkenlik için ilave işlem optimizasyonu ve tasarım geliştirme sağlamak için Yamaha’nın benzersiz tam hatlı çözümünü kullanmaktadır.

Ziyaretçiler ayrıca, inline AOI gücünü daha geniş bir dizgi makinası aralığı için daha erişilebilir hale getiren Yamaha’nın YSi-V ailesinin en yeni üyelerine de tanıtıldı. 5Mpixel ve 12Mpiksel makinelerin bir seçimi, lazer bileşen yüksekliği ve coplanarity kontrolünün ek avantajıyla birlikte, daha yüksek geri dönüş için yüksek hızlı TypeHS varyantlarındaki ek özellikler ile, çeşitli bütçeler için yüksek doğruluklu 3D AOI sunar.

Yamaha’nın tam hatlı çözümü, bu yılki Nürnberg kalabalığına hitap eden dahili verimlilik özelliklerine sahip YCP-10 gibi yüksek performanslı yazıcıları (screen printer) kapsıyor. Bunlara Yamaha orijinal açısal dönme kabiliyetli- tek squeegee (bıçak) kafa ve grafik ştencil / pcb hizalama, otomatik stencil temizleme ve opsiyonel priner içinde kontrol ve lehimleme-roll ölçümü dahildir..

Yamaha portföyü, kurulum, takip ve takip özelliklerine yardımcı olmak için kapsamlı bir yazıcı, dispenser, dizgi, 3D AOI, X-ray inceleme sistemleri, ileri robotik dizgi makinaları ve yazılımlar sunar. Kullanıcılar, otomatik beslemeli feederlar ve bulk feederlar, stick feederların kendinden kalibre edilme, özel yazılım araçları ve mobil uygulamalar gibi üretkenlik seçeneklerinden de yararlanabilirler.